Aim of the FMEA method

FMEA is an abbreviation for Failure Mode and Effects Analysis.

By applying the FMEA method during product and process development, potential errors are avoided preventively. The risk for your customers and your company is reduced.

What is special about the smart FMEA software?

As a training and consultancy company, we help our customers to apply management systems and quality methods with added value.

Our idea was to combine the intuitive usability of Excel with the possibilities of professional FMEA software!

The exceptionally close networking between smart FMEA modules

- Scope – planning and preparation

- Structural analysis

- Process flow chart

- FMEA (AIAG-VDA)

- Control Plan

- Ishikawa analysis

- Action management mail dispatch

- Dashboard for risk and measure status

ensures a consistent product development process (PEP).

Your company has product and process risk under control throughout the entire product life cycle!

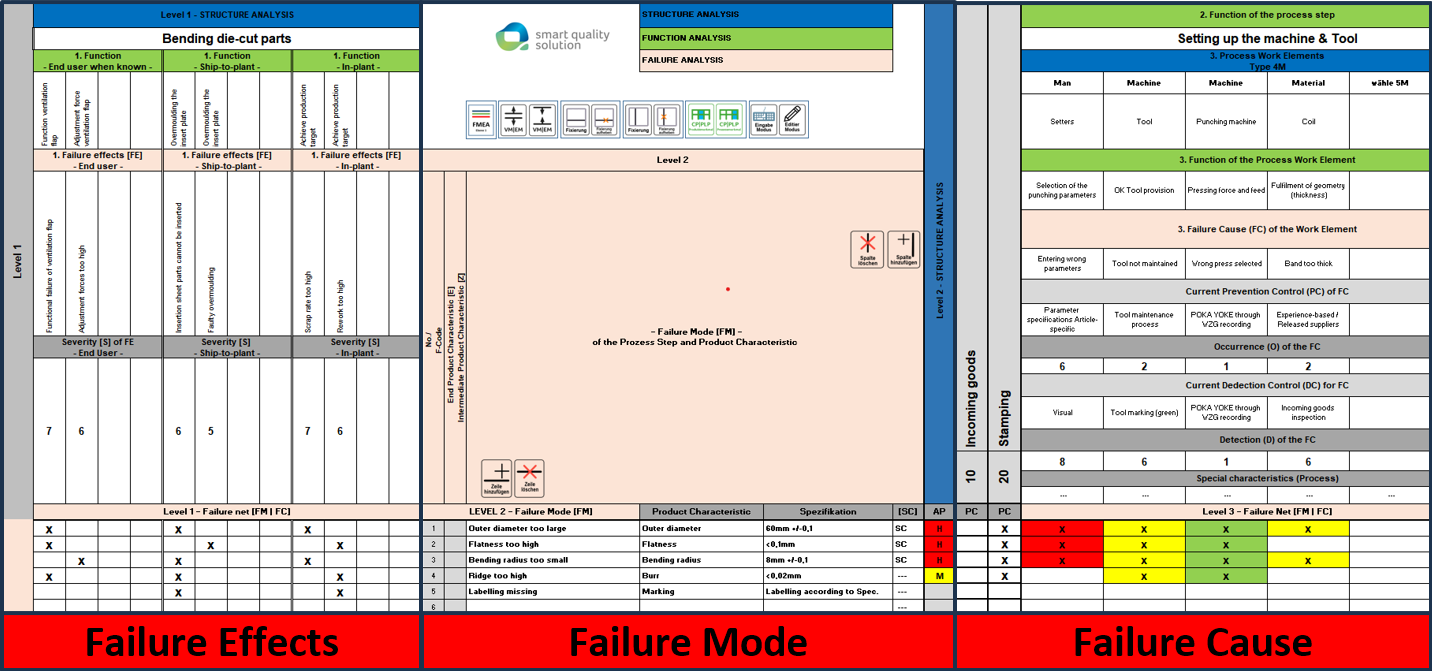

The heart is the smart input screen! This logic enables the simple linking of failure mode with failure effects and failure causes.

Simple. Clever.

Your FMEA team will be delighted!

Visit us at the European FMEA Congress in Vienna

FMEA freshly thought for you!

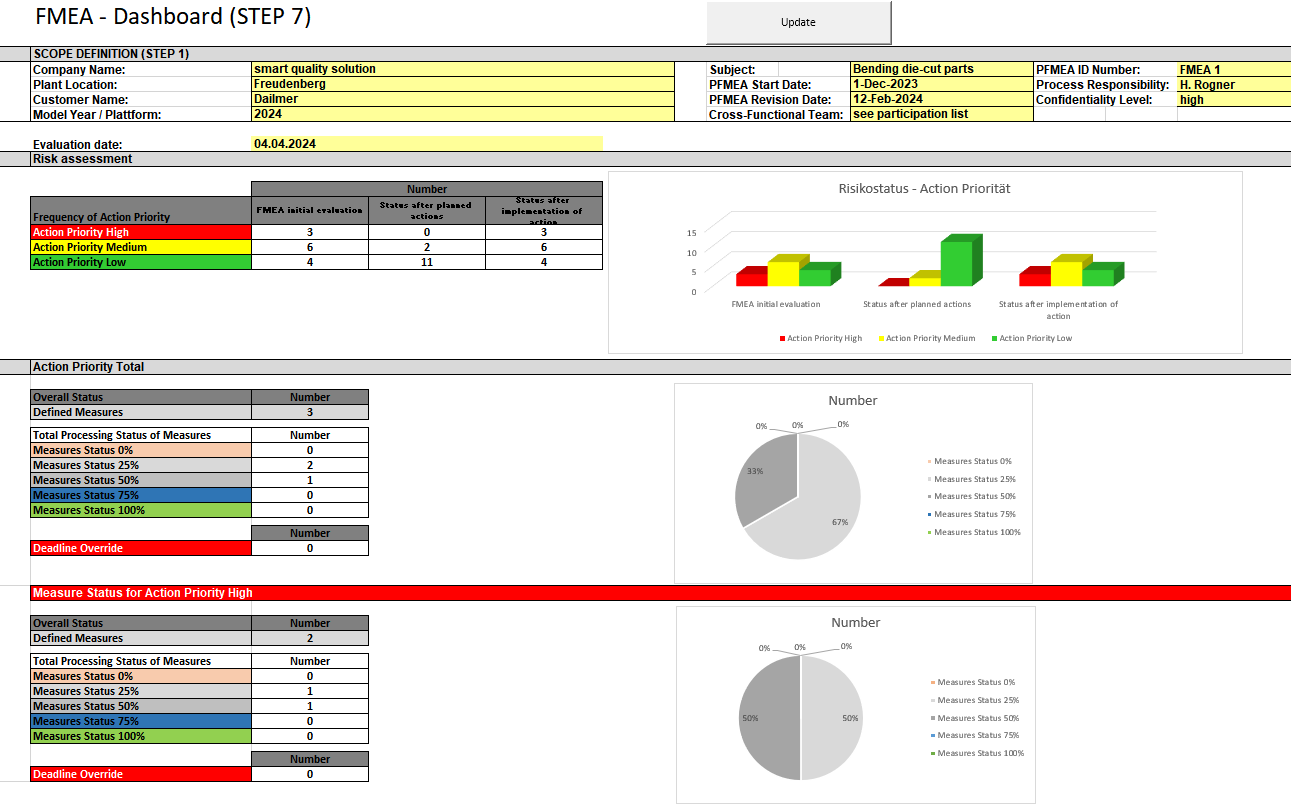

Risks under control

Whether risk management in product development (DFMEA) or process development (PFMEA), with our dashboard you always have an overview of the respective task priority and action status.

Thrilled customers

The clear and standard-compliant structure is easy for your partners to understand.

Reducing risk makes your products and processes safer. Your customers will thank you for it!

FMEA team happy

smart FMEA is the fastest way to create an FMEA!

This is made possible by our input matrix, with a design protected by the European Patent Office.

FMEA moderation is reduced to the essentials so that every team member understands the procedure. Time is used effectively as a resource!

Continuous documentation

Real added value is created by networking results.

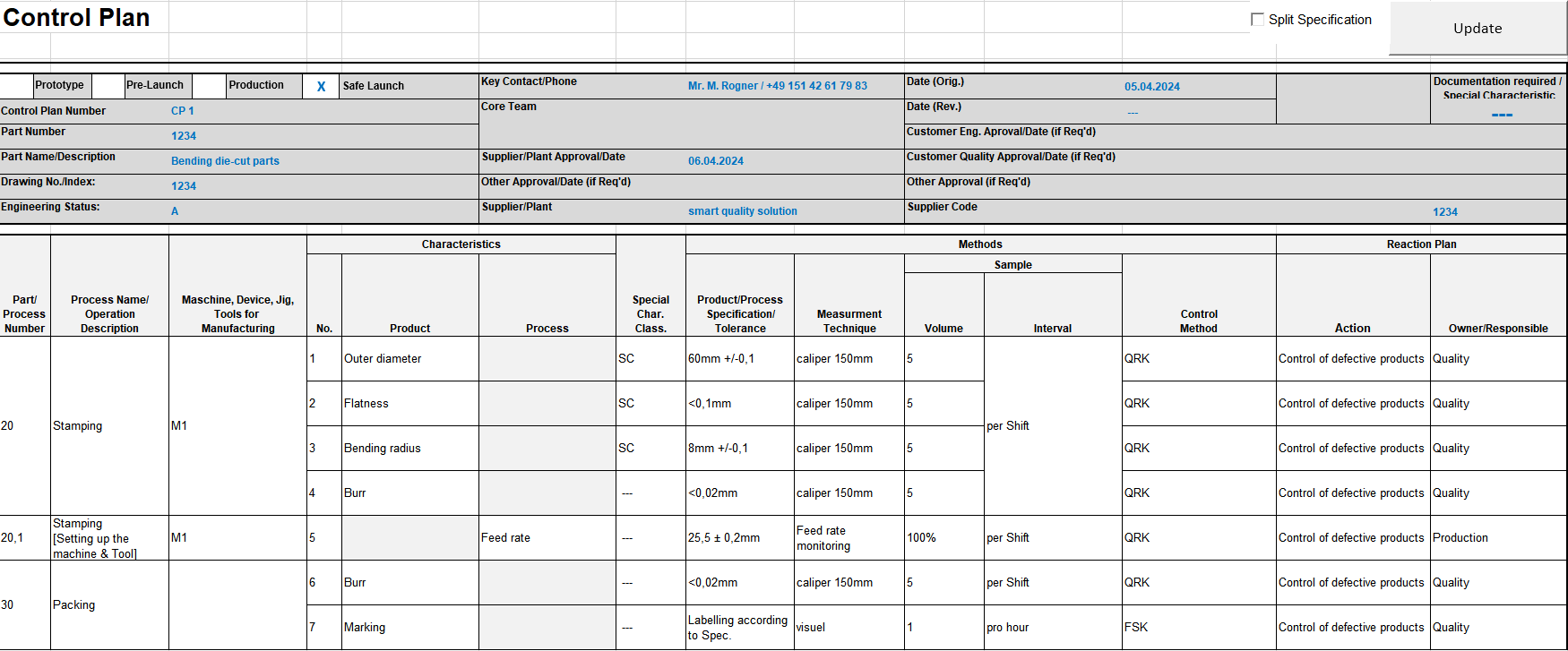

We combine knowledge across the board, from Process Flow Charts and FMEA with special features to Control Plans and Ishikawa analyses.

Knowledge management up to date

Lessons learnt are linked through our smart action management.

Findings, such as those from customer complaints, are simply assigned to FMEA measures. The FMEA becomes a knowledge management tool!

Money saved

In addition to all the advantages of the smart FMEA software, it is also one of the most cost-effective solutions in the professional FMEA software sector. This means you have more capital available for further investments in your company.

Our customers are thrilled!

Intuitive operation of the FMEA software

-

You save 70% of the training time for FMEA moderators

-

Your FMEA team understands the logic immediately – this leads to high acceptance!

50% time saving for you and your FMEA team

- Consistent use of the same data

- Describe types, consequences and causes of failure only once

- Generation of the failure network through simple linking

- Multilingualism of the software

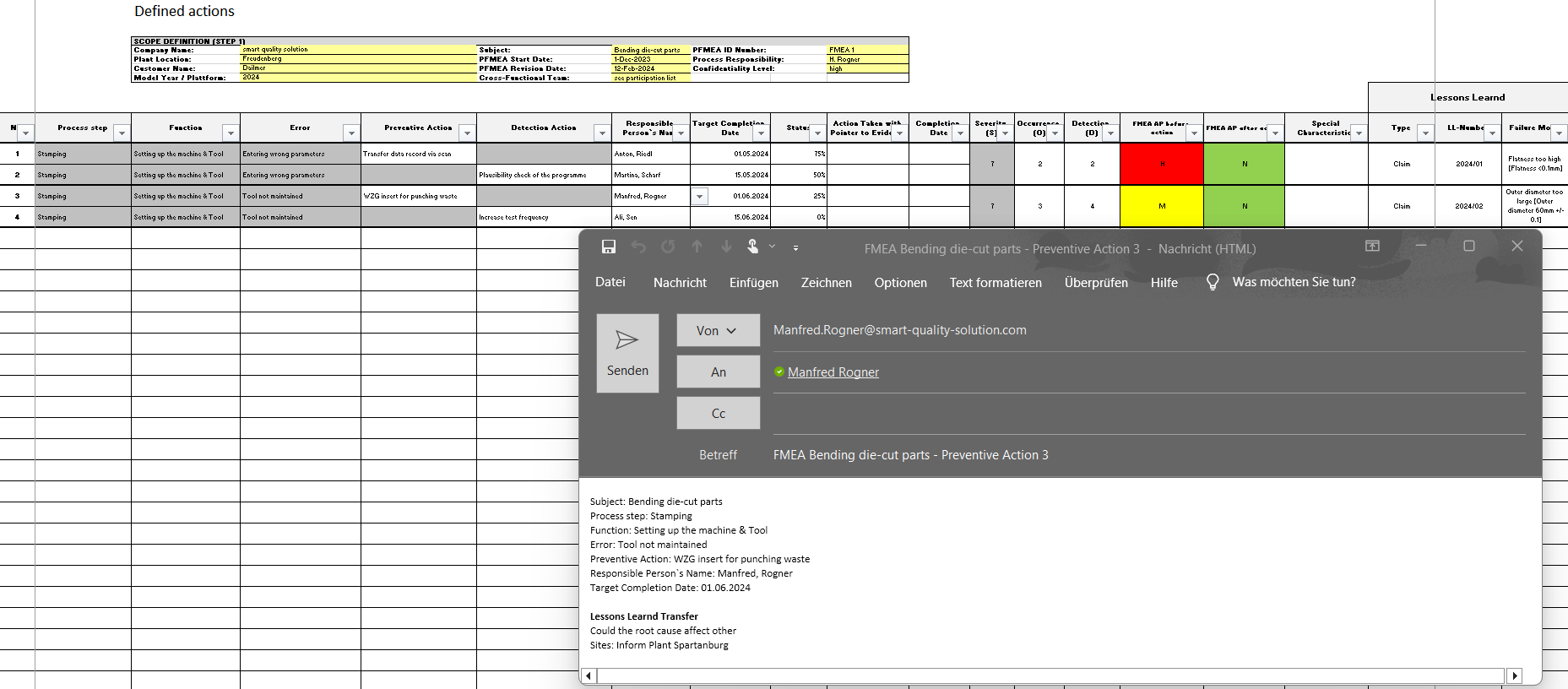

- Action management incl. mail dispatch

- Automatic calculation of task priority (AP)

100% end-to-end knowledge - from process flow chart to FMEA to control plan

- Best practice for FMEA planning and preparation

- Integrated process flow chart

- Automated generation of:

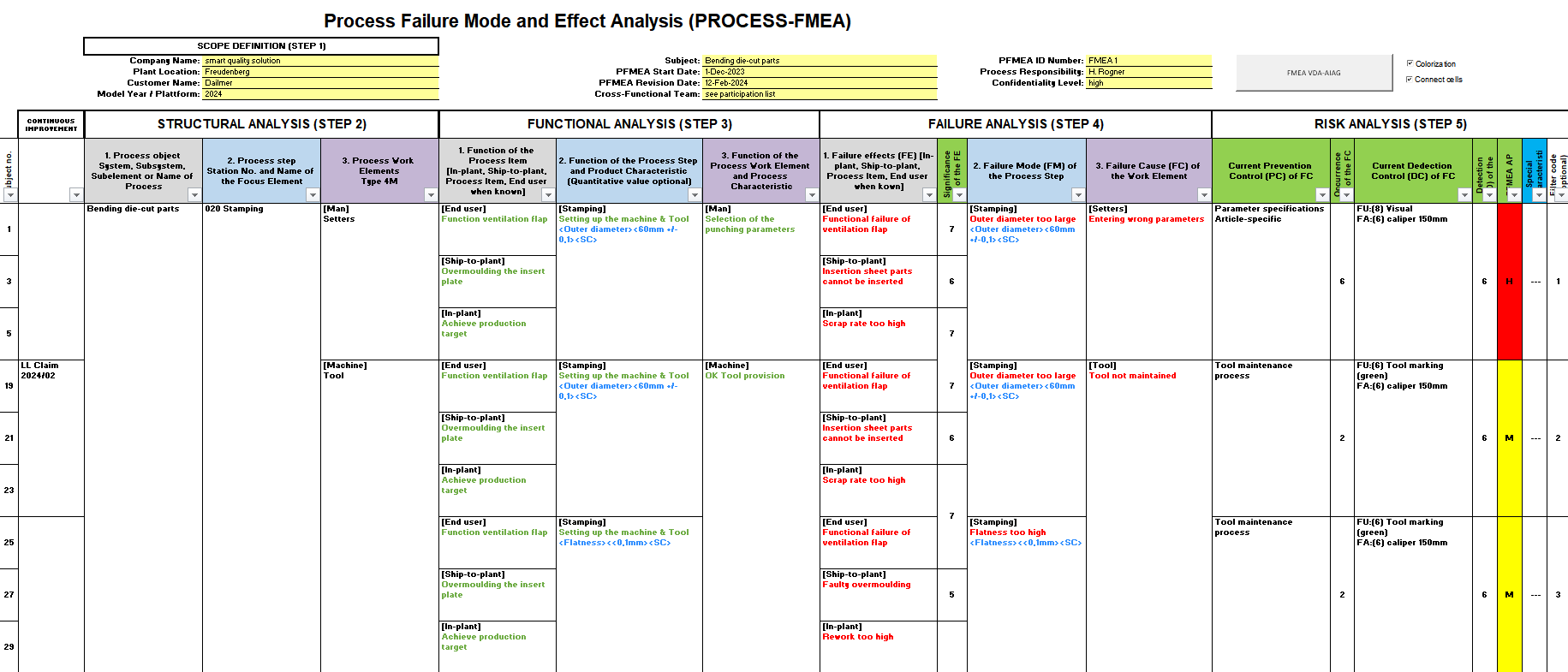

- FMEA in the VDA/AIAG form

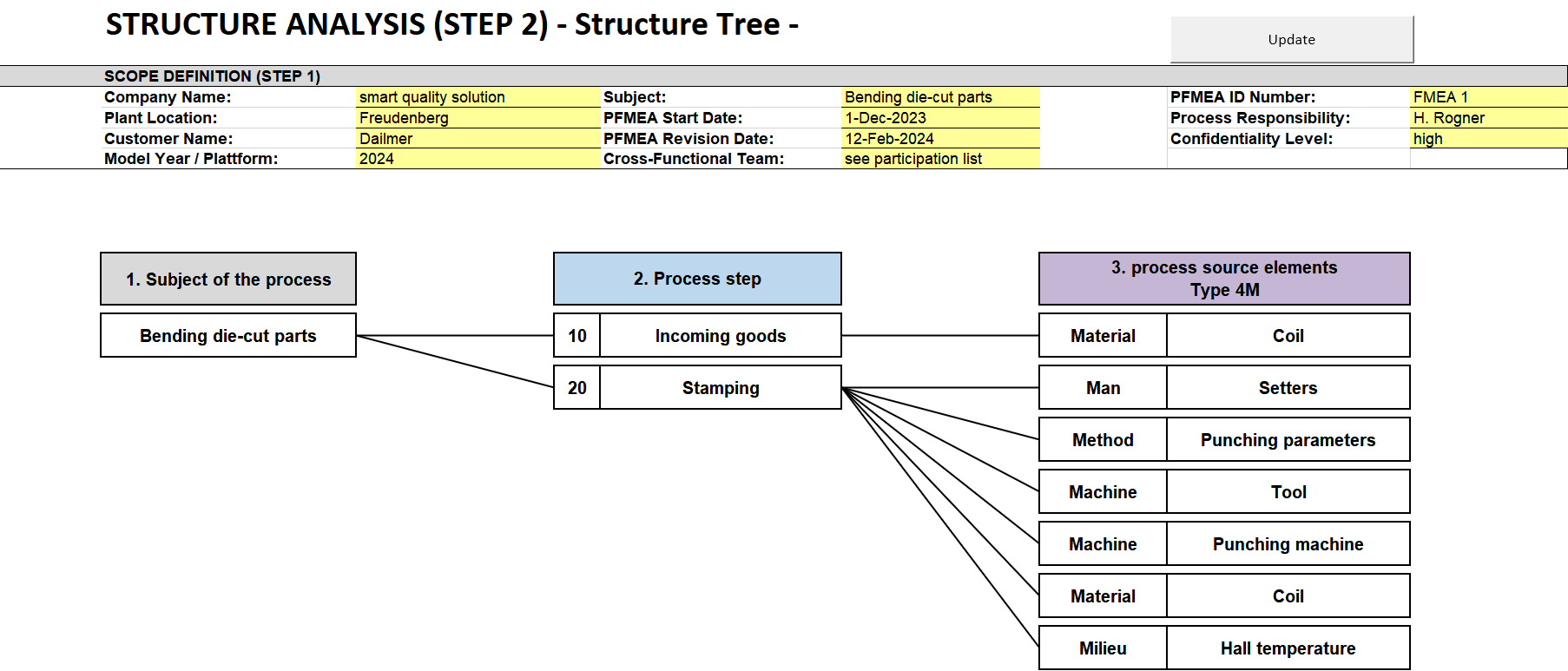

- Structure tree based on the FMEA

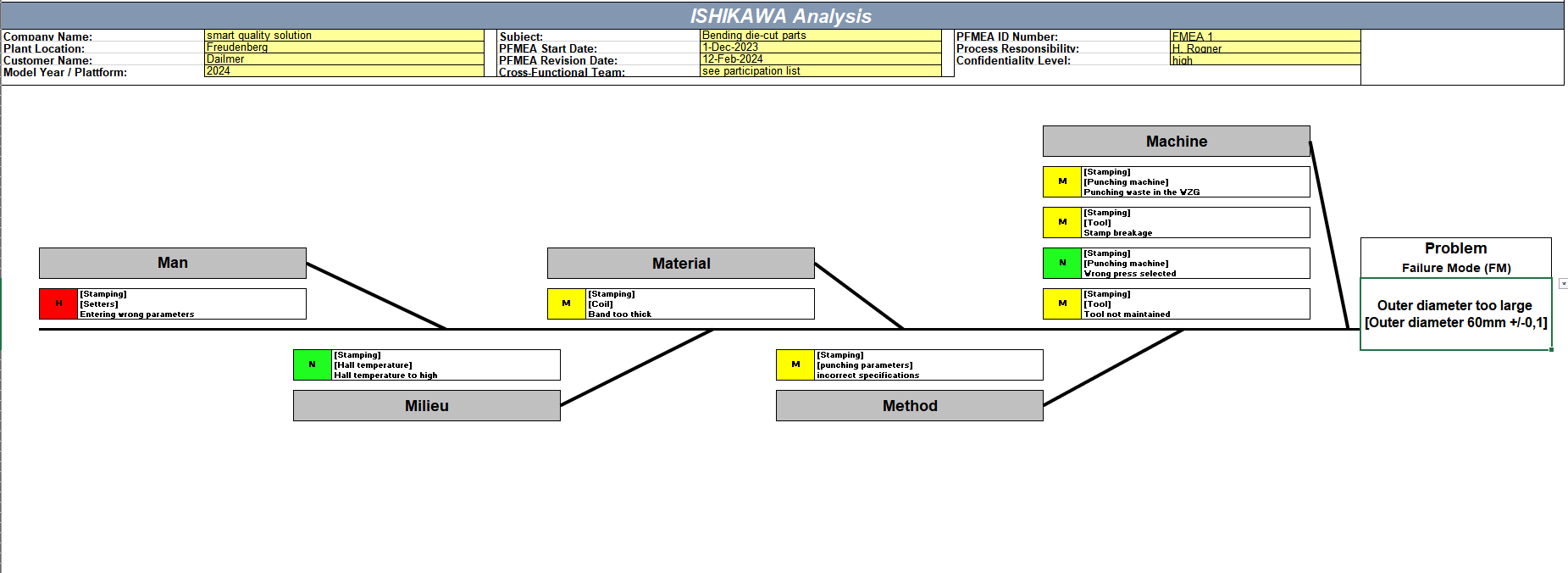

- Ishikawa analysis based on FMEA

- Control plan based on the FMEA

- Action management mail dispatch

- Change log

- Dashboard for task priority (AP) and action status

The solution for your company is: smart FMEA

-

Highly professional Excel FMEA software

or

-

Web-based browser FMEA software (cloud or on-premises)

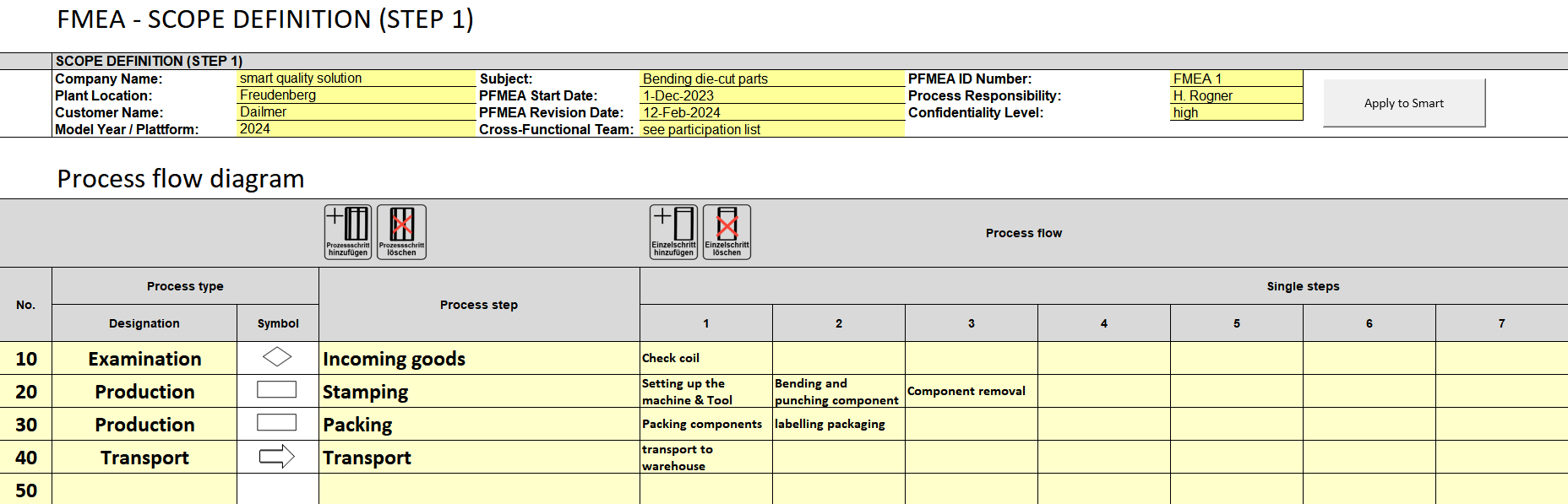

smart FMEA Example of a process FMEA for a stamped and bent component

Figure 1: Process flow chart

Figure 2: smart FMEA – Input screen

Figure 3: FMEA AIAG-VDA form

Figure 4: Control plan based on the FMEA

Figure 5: Ishikawa analysis based on the FMEA

Figure 6: Action management incl. mail dispatch

Figure 7: Structural analysis based on the FMEA

Figure 8: Dashboard for action priority and measure status

Figure 9: smart FMEA WEB browser application

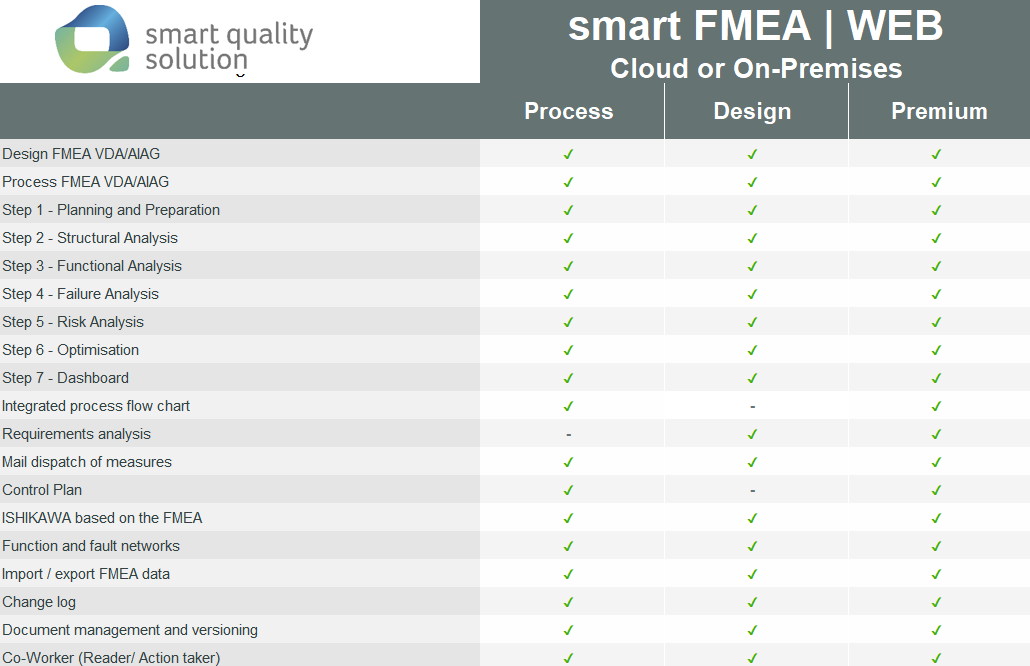

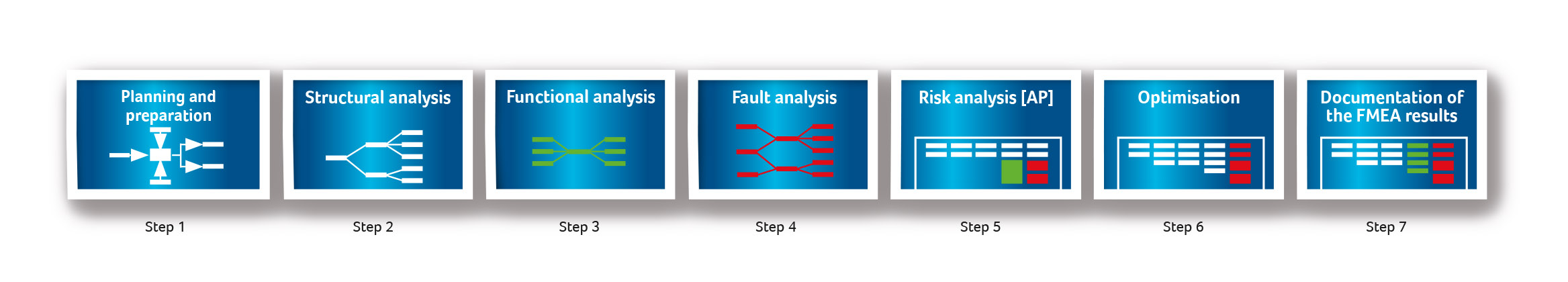

What steps are required to create an FMEA?

The FMEA is created in 7 steps in accordance with the harmonised AIAG & VDA standard:

- Step 1: Scope

- Step 2: Structural analysis

- Step 3: Functional analysis

- Step 4: Error analysis

- Step 5: Risk analysis [AP]

- Step 6: Optimisation

- Step 7: Documentation of the FMEA results

Figure 9: The 7 steps of FMEA creation

We would be happy to show you how you can utilise the full potential of the FMEA method for your company – contact us!

Email: manfred.rogner@smart-quality-solution.com

Mobile: +49 151 / 42 61 79 83